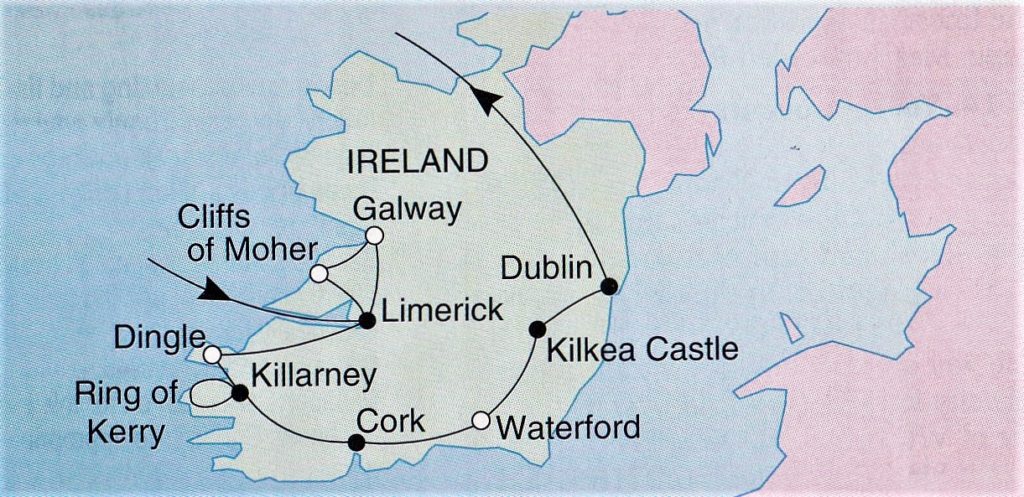

Years ago, when I was about to get married, I asked for crystal gifts rather than silver. After polishing the few pieces of silver that I owned, I knew that I never wanted any more of the stuff. Too. Much. Work. Lucky for me, I received many beautiful crystal pieces: bowls, picture frames and vases. Two of these gifts were Waterford Crystal. I knew that it was a good quality crystal but didn’t realize exactly how good until I visited the House of Waterford in Ireland two years later on a Collette Escorted tour.

My Waterford Crystal Collection

Visiting Waterford

I was delighted to find out that my crystal was named after an actual Irish town and that we would be stopping in Waterford for a guided factory tour.

House of Waterford Crystal Guided Factory Tour

George and William Penrose founded the company in 1783. WWRD Group Holdings Ltd., a luxury goods group, now owns the brand along with the Wedgwood and Royal Doulton brands.

Today, Waterford crystal is still hand-cut and produced with incredibly exacting attention to craftsmanship. As such, it remains a highly coveted and collectible brand, known for its quality and beauty.

The House of Waterford facility includes a factory, a retail store, exhibition area and a café.

Mould Room

The first stop on the tour was the mould room. Here Master Blowers flawlessly shaped the molten crystal with the use of wooden moulds and hand tools – a technique that has remained unchanged throughout the centuries.

Marking Department

As we moved through to the blowing platform, the crystal shapes started to form. Using the moulds, the skilled Master Blowers transformed glowing balls of crystal into various shapes before placing them through the 1400-degree furnace.

Marking Department

The next part of our journey was the marking department. Here they marked the crystal with a temporary geometric grid that assisted the Master Cutters as they cut the pattern onto the crystal. They cut each brilliant crystal piece strictly from memory, with these lines simply acting as a guideline for precision and accuracy.

Cutting Department

In the cutting department we saw the Master Cutters utilizing the skills they learned during an eight-year apprenticeship. The cutters learned and memorized each pattern, no matter how detailed, during their training years. Master Cutters applied the exact pressure to make the cut without damaging the integrity of the vessel.

Sculpting Department

In the sculpting department, inspirational pieces of crystal created by Master Sculptors, start out as solid blocks of crystal. They delicately adorn the intricate detail onto the crystal as they transform the blocks of crystal into elegant shapes and figures with their sculpting wheels.

Master Engravers

Finally, we saw Master Engravers at work. Using copper wheels, these skilled artisans patiently engraved intricate designs onto trophies and limited-edition pieces, a painstaking process that can take days to complete depending on the size and complexity of the design.

Quality Control

They carefully inspected the crystal at each stage of production to ensure each piece met their exacting standards. With six stringent inspection areas, only pieces that satisfy these standards made it to the next stage of production. They crushed items that did not pass the quality standards and melted them along with the other crystal making ingredients.

Waterford Crystal Retail Experience

With the largest collection of Waterford Crystal in the world, the opulent 12,000 square feet retail store represents the entire catalogue of luxury crystal, including an exhibition of their golf and world sports trophies. And no, I did not buy anything. Breathtakingly beautiful but much too pricey.

House of Waterford

Waterford Retail Showroom

Waterford Crystal Chandeliers

In 1966, Westminster Abbey in London installed sixteen Waterford Crystal chandeliers for the 900th-anniversary dedication of the church. The Guinness family actually paid for them. Other chandeliers also hang in Windsor Castle and the Kennedy Center in Washington, D.C

Waterford Crystal New Year’s Eve Ball

There have been 5 manifestations of the crystal ball. Since 1998, Waterford designed the 4th and 5th versions of the ball. In 2009 they introduced the current version, number 5. It is an icosahedral geodesic sphere lit by 32,256 LED lamps. Its diameter is twice as wide as the 2008 ball, at 12 feet, and contains 2,688 Waterford Crystal panels, with a weight of 11,875 pounds. It was designed to be weatherproof, as the ball would now be displayed atop One Times Square nearly year-round following the celebrations.

Trophies

Waterford crystal is a popular choice for trophies at global events such as those featured at The French and German Grand Prix Formula One, the Tennis Master Series, the Volvo Ocean Challenge and even the People’s Choice Awards.

How to Identify Waterford Crystal

While writing this article, I decided to check for the Waterford stamp on my crystal pieces. Since 1950, each piece of Waterford crystal has been stamped with the company logo. Resembling a stencil pattern, the Waterford name is slightly opaque. On a wine glass, it’s found on the underside of the base. If the piece is older, a magnifying glass may be necessary to find the stamp due to wear.

With the help of a bright light and magnifying glass, I spent at least 15 minutes searching every nook and crevice (and there were many) until I found all three tiny Gothic script stamps.

Summary

Ireland is a wonderful place to visit, rural and full of friendly people.

If you love crystal as I do, you will love the House of Waterford Crystal Guided Factory Tour in Ireland. The guided tour of the factory included a visit to all aspects of traditional crystal production. It takes approximately 1 hour and 30 minutes. You can take photos and film both on the tour of the factory and in the retail store.

Tour of Ireland

Waterford Crystal: A Sparkling blog Crusin Lady. Thanks.

I understand that Waterford is now made in countries other than Ireland in countries such as Slovenia, the Czech Republic, Hungary and Germany. How can I tell where my pieces have been made?

Yes. They are made in all those other countries but they maintain the same standards of production that I described.

When Elaine D. and I went to Ireland, we didn’t go to the Waterford factory. After reading your article, I wish we had.

Wow I have a whole new respect for this crystal! I’ll have to add the factory to my to do list!

Waterford Crystal is so beautiful! I didn’t realise you can visit the factory! I love crafts and the attention to detail in these pieces is crazy! I’d love to experience seeing them made! Thanks for the wonderful guide!

This must have been such a great tour to go on! I would love to see how they make them as I know my mum really likes them and has a few pieces.

I visited Waterford when I was 19, on our way to camp down in Duncannon! I always loved the Waterford crystal in a nostalgic way as a result.

How beautiful! I was given a Waterford crystal vase for our wedding but didn’t know the history behind it, other than it was special! i would love to do a tour sometime!